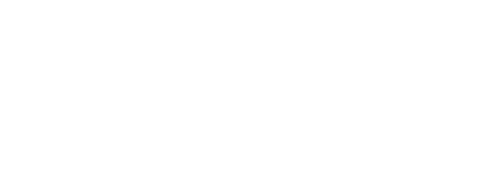

DOUBLE EDGE EXTRUSIONS

Side, top, and bottom panels are fitted into double edge aluminum extrusions and driven into the wood.

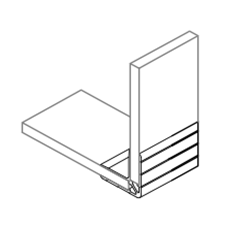

CAST METAL CORNERS

Our integrated valance clamp is the strongest way on the market to make a strong and tight closure.

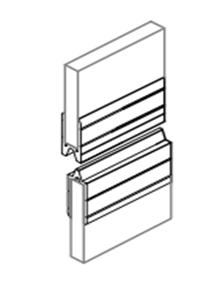

MALE/FEMALE VALANCES

Male and female extruded aluminum valances assure a tight closure.

707-994-6363

Parker Plastics Fabricated Cases

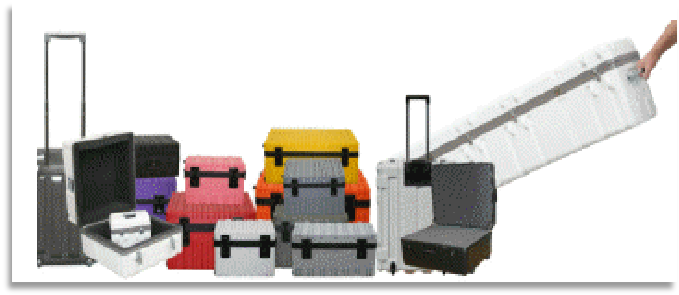

Our fabricated cases are built to your exact specifications using only the highest quality materials. Walls are constructed from ABS laminated over plywood, or plastic panels and riveted to aluminum double edging with steel ball corners. Tongue and groove valance extrusions are precisely cut to insure a perfect closure. Lids are secured with heavy-duty full-length piano hinges. Our custom-built fabricated cases meet the toughest requirements found in military, aerospace, oil and gas, automation, government, security and telecommunications applications.

Built to meet your exact specifications

Designed to meet Air Transport Association (ATA)

Unlimited interior and size options

Standard Features:

ABS panels laminated to top quality plywood 1/4”, 3/8”, and 1/2” thick

Blind rivets secure aluminum extrusion to wall material

Full length steel piano hinges for hinged lid cases

Steel ball corners

Aluminum tongue and groove valances

Recessed steel valance spanning twist latches and handles

10-32 tapped steel rack rails installed in rack / shock mount cases

Options

Wheels, casters and telescopic pull-handles

Choice of colors (black is standard)

Plastic panel laminates 1/4”, 3/8”, and 1/2” thick

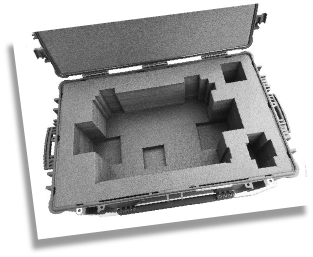

Foam filling, foam lined, or with custom foam

Locking Latches

D-Rings

Card holders

Dividers

Removable lid

Reverse application

Foam shock mounting available for rack mount cases

Aluminum tube fork lift skids

Folding Ramp for unloading and loading of equipment

Field workstations and console stands

And more just ask